Introduction

In the quick-paced world of producing and good quality guarantee, precision is key. Companies consistently strive to raise their strategies for higher outcomes, and one mighty manner to reach this is thru effectual calibration practices. This article delves into a compelling case be trained that showcases how one supplier appreciably improved its operational effectivity through revamping its calibration systems.

The story we are approximately to unfold isn't very virtually numbers or methodologies; it’s about a transformation that demonstrates the pivotal function of true calibration in accomplishing operational excellence. By utilising superior procedures and fostering a culture of continuous enchancment, this employer now not most effective extended its standards yet additionally set a benchmark for others inside the market.

Understanding Calibration: What Is It?

Calibration is the activity of fixing and verifying the accuracy of measurement contraptions. In effortless terms, it ensures that methods provide specific readings. The significance of calibration will not be overstated, exceedingly in industries wherein each and every aspect counts.

Why Is Calibration Important?

Accuracy: Accurate measurements bring about better product good quality. Compliance: Many industries are situation to strict policies that require normal calibration. Cost-Efficiency: Reducing blunders can keep corporations time and cash. Safety: Ensuring that machine operates within riskless parameters protects staff and items alike.Industry Standards for Calibration

Different industries have distinct criteria for calibration practices:

- ISO 9001: Quality leadership techniques. NIST (National Institute of Standards and Technology): Calibration guidelines within the U.S. GMP (Good Manufacturing Practices): Regulations for pharmaceutical industries.

These requirements lend a hand agencies protect consistency and high quality across their operations.

Case Study Overview

Company Background

The issuer on the heart of our case study is XYZ Corp, a mid-sized manufacturing enterprise specializing in precision formulation for aerospace applications. With a reputation built on reliability, XYZ Corp faced rising strain to fulfill stringent market criteria even as managing quotes without problems.

Challenges Faced by way of XYZ Corp

Inconsistent Measurements: Variability in dimension resulted in production delays. Regulatory Compliance: Struggles with adhering to market restrictions multiplied scrutiny from prospects. High Costs: Inefficient calibration processes inflated operational prices. Employee Morale: Frustration among workers thanks to common mistakes impacted productivity.Deciding to Change

With those challenges looming sizable, XYZ Corp's leadership identified the want for substitute. They initiated an in depth diagnosis of their latest calibration practices, which found out brilliant room for enchancment.

Implementing New Calibration Practices

Step 1: Assessment of Current Processes

The first step became assessing current practices by means of audits and worker feedback periods. This helped identify bottlenecks and locations needing rapid focus.

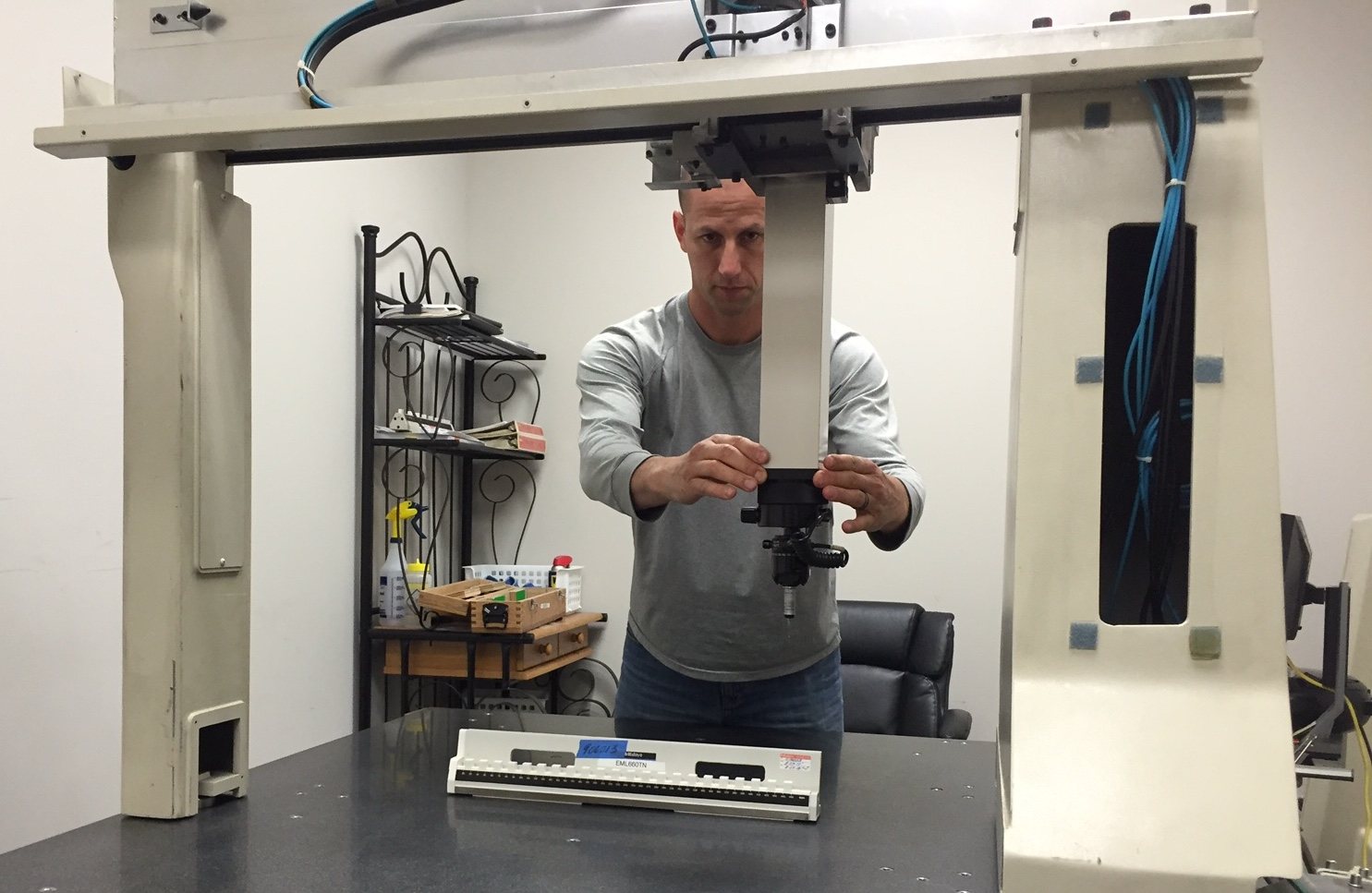

Step 2: Investing in Technology

XYZ Corp made up our minds to spend money on modern day calibration applied sciences:

- Automated Calibration Systems Software Solutions for Data Tracking Advanced Measurement Tools

By integrating technologies into their processes, they aimed to in the reduction of human error enormously.

Step 3: Training Staff on Best Practices

One important facet was once practicing people on new system and superior practices:

- Workshops on acceptable usage Regular refresher courses Real-time challenge-fixing sessions

This funding in human capital ensured that everyone was once aligned with the agency's new goals.

Step four: Establishing a Calibration Schedule

Creating a scientific NIST oscilloscope calibration schedule for calibrating package grew to be crucial:

| Equipment Type | Frequency of Calibration | Responsible Team | |-----------------|---------------------------|------------------| | Measurement Tools | Monthly | Quality Control | | Production Machines | Quarterly | Maintenance | | Safety Equipment | Biannually | Safety Officer |

This proactive way minimized downtime and greater reliability.

Measuring Success Post-Implementation

Key Performance Indicators (KPIs) Used

To review good fortune publish-implementation, XYZ Corp focused on numerous KPIs:

Error Rate Reduction Production Downtime Employee Satisfaction Scores Regulatory Compliance RatesBy tracking those metrics, they may gauge advancements appropriately.

Results Achieved After Implementing New Practices

After imposing new calibration practices, XYZ Corp witnessed fantastic effects:

- A 30% discount in errors rates A 25% cut down in production downtime Enhanced worker morale contemplated in pride scores growing by 40%

These consequences placed them as leaders inside their sector.

Case Study Analysis: Key Takeaways from XYZ Corp's Journey

1. Emphasizing Continuous Improvement is Crucial

XYZ Corp’s trip underscores the value of continual development—a philosophy that should always be embedded inside of every supplier aiming for excellence.

2. Technology Can Be Transformational

Investing in glossy expertise not simply streamlines methods however additionally empowers laborers by lowering their workload on the topic of manual tasks.

3. Employee Engagement Matters

Training techniques foster a feel of ownership between employees, which translates into more suitable functionality and satisfaction degrees.

FAQs About Calibration Practices

Q1: What is the rationale of calibrating measuring contraptions?

Calibration ensures that measuring gadgets furnish appropriate readings, that's central for maintaining product first-rate and compliance with regulatory standards.

Q2: How regularly should I calibrate my accessories?

The frequency relies on various factors similar to utilization depth and company recommendations; on the other hand, developing a usual agenda stylish in your selected context is recommended.

Q3: What technology are obtainable for calibration?

Modern technologies comprise automated calibration strategies, software strategies for documents monitoring, and evolved dimension gear designed to make stronger accuracy whereas minimizing human error.

Q4: Can fallacious calibration impact safeguard?

Yes! Improperly calibrated kit can cause harmful prerequisites each for employees and finish-users if products do now not meet defense specifications.

Q5: What are some known challenges confronted throughout the time of calibration?

Common challenges include inconsistent measurements, top operational costs by way of inefficiencies, concern adhering to laws, and occasional worker morale stemming from regular blunders.

Q6: How does one measure good fortune after imposing new calibration practices?

Success is also measured employing key functionality symptoms (KPIs) which include mistakes cost relief, manufacturing downtime metrics, worker satisfaction ratings, and regulatory compliance prices put up-calibration transformations.

Conclusion

In end, this example learn illustrates how XYZ Corp accurately superior potency through stronger calibration practices—demonstrating that investing time and assets into refining such processes yields great returns the two financially and operationally.

As establishments preserve navigating complexities inside their respective industries, prioritizing mighty calibration ideas will positively pave the way towards sustained achievement while meeting patron expectancies constantly—thereby putting a usual deserving emulation throughout sectors!

This article serves as an insightful exploration into how one provider navigated its demanding situations by strategic differences in its calibration practices at the same time highlighting broader implications principal throughout loads of industries handling precision measurement necessities—making it a useful study for all hunting toward improving operational effectiveness!